|

|

|

|

|

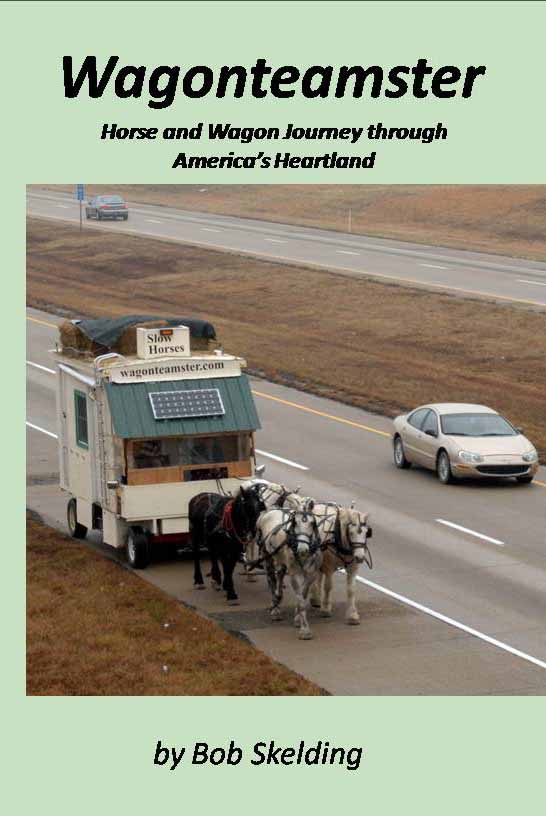

Wagonteamster

|

|

|

|

|

|

|

|

|

This article is intended to show the basics of horseshoeing. Please get a little more experience before you try it yourself.

Horses have to have new shoes every 6 to 8 weeks for 3 primary reasons: the hoof grows downward about 3/8 to 1/2 inch in this time, the shoes wear & the nail heads wear.

In this article Im resetting Joyces front shoes and putting new ones on the rear.

|

|

|

|

1. The first step is remove the old shoe. In these next two pictures Im doing that. First I cut the old nail clinches (when the shoe is put on the ends of the nails are folded over to hold the nail on).

In the next picture, Im using a tool called the pullers to remove the old shoe. I start at the heel of the shoe and pry it upward a little. Then I start pulling the nails out. In the end I pull the shoe off. Pull in with the pullers so you dont rip off a piece of the outside hoof wall.

|

|

|

|

2. Then the hoof has to be prepared for the new shoe. Basically, we have to trim away about 3/8 of an inch of old hoof. Here Im using a hoof knife to cut away excess frog (the fleshy V in the bottom center), I also cut a 3/8 inch deep channel about 1/2 inch from the edge of the hoof. This is so my nippers can trim the hoof wall back. I also scrape away a little bit of the sole towards the middle.

There are two hoof knives, one for the left hand and one for the right. The left hand knife Im using has the cutting edge closest to me.

|

|

|

|

3. Then the hoof wall is trimmed with the nippers. You have to be very careful here to trim it so you will have a flat hoof. The toe seems to grow faster then the heel, so only trim about 3/16 from the heel and trim on a slant, so you trim 3/8 to 1/2 at the toe. If you take too much hoof from the heel, it will cause the horses heel to drop, stretching the large tendon in the back of his leg (flexure tendon) and cause him to go lame.

|

|

|

4. After the wall is trimmed, the hoof is rasped flat. This is done so that the shoe has a flat surface to sit on. It also gives the final shape to the hoof. For a final shape you want the horse to be balanced over his feet, with both hooves the same height. Angle is important too. The outside of the hoof should slant up at a 45 to 55 degree angle.

Some farriers dont use a rasp. They still do it the old way where they just press a hot shoe on the hoof so the shoe will sit flat.

|

|

|

|

|

|

|

|

|

|

|

|

5. Since I use horseshoes with toe clips, Im cutting a notch for the clip. Many horseshoes use side clips or no clips so this would not be necessary. This picture shoes the white line (about 1/4 below my nippers). The inside of this line marks the line between the hoof wall and the inner sole. When hammering in a nail it has to go to the outside of the inside of the white line. If it went inside, the nail would hit the inner-sensitive sole and the horse could go lame. If you do this by accident, youll see blood. Pull the shoe, heat a rod and cauterize the wound.

|

|

|

In this picture, Joyces right foot (your left) is ready for a shoe, her left is not. You can see that the right hoof is shorter, shes more up on the toe (like she should be) and the hoof is balanced and carries her weight equally.

|

|

|

|

6. Here Im fitting the new shoe for her foot. Since, Im resetting this shoe, I didnt have to do anything. On her rear shoes which were new, I had to use a hammer to bend the shoe in about 3/8 to make it fit. Its easier to bend horseshoes hot, but if youre careful, you can bend them cold. The nail holes for the properly fitted shoe should line up with the middle to the outside edge of the white line on the hoof.

|

|

|

|

Before we nail on the shoe, I wanted to explain a little about shoes and nails. The heads of the nails are tapered, as are the insides of the nail holes on the shoe. This allows the shoes and nails to wear and still keep the shoe in place. The heads of the nails have a side with a burl and a flat side. The burl always points to the inside of the shoe. This is because the nail tips are slightly curved so that the nail wants to drive away from the inner sole and come out the outside of the wall.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

7. Nailing on a shoe can be quite a trick the first time you do it. The shoe has to be held in the right spot. The nail has to be held straight and you have to swing the hammer (all with two hands). Drive the nails straight in (with the burl on the nail head towards the inside of the hoof). Make sure the nail point comes out the outside of the hoof.

After the nail is fully seated, use the claw to twist off the excess point protruding from the outside of the hoof. This is important. If the horse has to put his foot down, a protruding nail point can slice you open pretty good.

|

|

|

|

Here you can see the hoof with two nails coming out each side (I later added a third nail to each side). The points are twisted off. To ensure that the nails firmly holds the shoe on, Ill have to clinch the nails (bend over the protruding ends).

You can also see in this picture the old nail holes (located lower on the hoof as I trimmed off about 3/8 of old hoof.)

|

|

|

|

8. Here Im using a hammer to clinch the nails. Most farriers use a clincher and I have one too, but mine isnt big enough for draft horses, so I usually hammer clinch the nails. This works better on a hard surface like a driveway.

|

|

|

|

9. Using the back of the rasp to file away excess hoof wall (hanging over the outside of the shoe.) I have Joyces foot resting on my knee. Most farriers today use a little stand, but Im doing it the old fashioned way.

|

|

|

|

This is the finished product.

|

|

|

|

Draft horses tend to wear out their rear shoes faster then the fronts (especially the outside edges.) This is because most of the force used to pull a load comes from the hindquarters. Riding horses usually wear out the front shoes faster as 2/3 of the horses weight is on their front feet.

Trotting a horse on pavement will cause shoes and bare feet to wear much faster. Here a side view of the old and new rear shoes after six weeks of moderate road work pulling a wagon.

|

|

|

This is a view of the tools required to shoe a horse. When buying farrier tools, always buy the best - cheap ones dont last.

Chaps are important to not only protect the leg, but also to provide some friction between the outside of the hoof and your lap/legs to keep the hoof in place while you work.

|

|

|

|

|

|

From left to right, the tools are: 1. Small claw hammer for nailing shoes. 2. A large hammer for shaping shoes (a forge and an anvil help, but a hammer and any hard surface will make do.) 3. Clinchers 4. Left and Right Hoof Knives 5. Rasp 6. Nippers 7. Shoe pullers

|

|

|

|

I hope you enjoyed this little introduction to shoeing a horse!

|

|